CISDI’s many successes in 2024

Date:2025/1/15 Source: CISDI

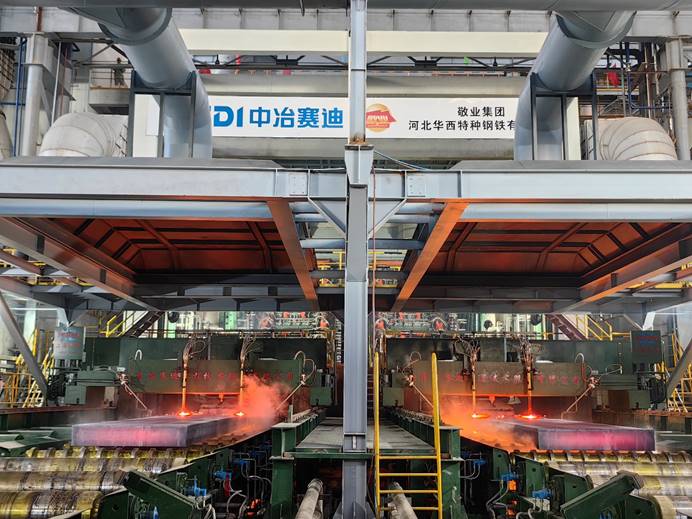

Huaxi Special Steel’s 2,600mm-wide slab caster was hot tested

A 2-strand thick slab caster was hot tested at Huaxi Special Steel in China’s Hebei Province in December 2024.

CISDI built the caster to an EPC mode. It features:

● An expert roller apron design for continuous bending and straightening

● Mould’s hydraulic oscillation

● Mould’s online electric regulation of widths

● Mould’s expert system

● 3D dynamic secondary cooling model

● Dynamic soft reduction

● A heavy reduction model.

The application of tech for strand’s vertical lifting has solved a hot charging issue caused by elevation differences between the casting and the rolling plants.

The Huaxi caster will be capable of producing the thickest (400mm) and widest (2,600mm) specifications.

It took 10 months to hot test the caster and a twin ladle furnace and utilities, and to rebuild relevant workshop buildings.

CISDI’s mills now playing star role at Zizhu’s new sections rolling line

CISDI Equipment Co pulled out all the stops to rapidly provide mill supplies and hot commissioning technical services for a sections rolling line (mill barrel’s diameter Ø550mm) at Zizhu Group in China’s Liaoning Province.

It took only eight months to fulfill the line project, which was completed in December 2024. This swift result was critical to Zizhu’s product expansion and optimisation programme.

Products will cover a wide range of varieties and specifications, including light rails, angles for tower structures, bulb steels and mining I beams.

In addition to advanced steel rail pre-bending, long-length straightening and automatic piling tech and equipment, CISDI’s core equipment - the movable breakdown mill BDM580 and the short-stress path rolling mill NUMC250 - have created a reliable semi-continuous rolling design.

These mills have a compact structure, high rigidity and superb stability and give convenient operation and easy maintenance. They will ensure a precise production of all sections.

China’s first vertical, open-fire ZnAlMg-coating line discharged perfect coil

CISDI Thermal and Environmental Engineering Co’s unique solutions enabled Xinyu Colour Plate Co to stably produce perfect ZnAlMg-coated coils with a high standard of surface quality, mechanical property and corrosion resistance.

CISDI Thermal was responsible for all-line designs, core equipment integration and supplies for Xinyu’s new vertical, open-fire ZnAlMg-coating line, which was started up in April 2024.

It will produce 350,000 tonnes of high-performing products a year for sectors producing photovoltaic brackets, household appliances, high-end colour feedstock and building plates.

CISDI Thermal’s unique ZnAlMg-coating solutions account for over 80 per cent of China’s market and are also operating smoothly at Shougang, Ansteel, Pangang and New Tianjin Steel.

CISDI Electric’s high-performance MV AC-DC-AC frequency converter performing well in Spain

CISDI Electric’s star frequency converter has been operating with great success for Spanish steel giant Sidenor Aceros Especiales S.L since mid November 2024.

Sidenor is a European leader of special steel long product rolling and Spain’s largest special steel producer.

To meet Sidenor's drive system modification for its open-train mill, CISDI Electric designed and supplied a high-performance 5MVA AC-DC-AC frequency converter with a motor power of 3,000 kilowatts and a speed regulation range of 20 to 55 hertz.

“CISDI Electric’s product completely satisfies all our process requirements”, commented a head of the Spanish plant.

The frequency converter passed multiple rolling testing first time for a wide range of specifications for 90 to 230mm products. All results showcased a torque response time of faster than 5 milliseconds.

First ‘made in China’ 1,750mm-spec 5-stand tandem cold mill launched

October marked the launch of China’s first self-made 5-stand 6-hi TCM, when a pickling line-tandem cold mill with a specification of 1,750mm was hot commissioned at HBIS Yanyang Cold Rolling Co.

The Hebei Province’s PL-TCM features three of CISDI’s leading technical developments - the 5-stand 6-hi tandem cold mill, rotary drum flying shear and innovative dual-drum coiler.

It will produce 1.60million tonnes a year. Its main products - hot-rolled low carbon steel, ultra-low carbon steel (IF) and high-strength steel (HSS980) will feature a thickness range of 0.3-2.5mm and a width range of 1,000-1,630mm.

Feedstocks will have correlative dimensions - 2-6mm thicknesses and 1,000-1,630mm widths.

The production line will serve the sector producing steel sheet for high-end household appliances and automobiles, and is set to rank as a standout example of smart and efficient manufacturing.