Specialised topic: 2019 – a year of success for CISDI (Part 1)

Date:2020/4/17 Source: CISDI

CISDI saw many

achievements in 2019. The company hit its budget goals and reached new highs in

income and revenue.

Steel remained

at the core of the business and numerous international partnerships were

strengthened during the year. CISDigital’s products attracted ever-more

attention from customers in China and overseas.

The company’s

ongoing commitment to the research and development of green steel technology

was rewarded with numerous applications for clients around the globe. A number

of industry firsts were successfully constructed and started up.

Section 1: Steel business strengthens

In 2019 CISDI

focussed on green and intelligent manufacturing, providing core products for

its major

customers.

The company has

grasped opportunities presented by China’s aim to cut backward production

capacity through upgrade and transformation, relocated projects for

environmental protection and from M&A.

CISDI has

successfully carried out many major projects, such as the engineering for Baowu

Group’s Zhanjiang blast furnace 3 and its related plants, plus Baosteel

Desheng’s Stainless Steel Plant.

CISDI’s

eco-friendly, intelligent stockyard took over 60 per cent of China’s market share.

CISDI’s

consultancy expertise led master plans for Baowu Group’s Yancheng Steel Plant

and the Jinxi Fangchenggang Steel Plant.

Baowu Group’s

Zhanjiang Steel gained a Chinese national project prize for excellence thanks

to CISDI’s decade-long role as master designer and main supplier.

Hard work has

enabled CISDI to forge deeper integration between CISDI Equipment bases and

process designs. Commercialisation and application of the company’s core

technologies and innovations have been pushed forward.

Over the past

year, Chinese and overseas markets embraced CISDI’s stockyard clean transfer

technology. Steelmakers welcomed CISDI’s granulating drum technology, its SACS blast

oxygen furnace with a 4-point linkage suspension system, ladle furnace and tube

rolling mill expertise.

In addition,

CISDI’s hot mill skin pass mill continued to perform with world-leading

indicators and its skip hoist accounted for over 90 per cent of China’s market

share.

There were a

number of impressive firsts, too – CISDI’s

first piercer mill for tubular products, its first electro-hydraulic

direct-drive mould vibrator for continuous caster and its first universal mill

for sections rolling line all found their niche in the Chinese market.

Zhanjiang

Steel’s BF3 launched

Baowu Group’s

Zhanjiang blast furnace 3 plant was launched in March 2019. The engineering of

the plant was undertaken by CISDI. This included the stockyard, blast furnace,

hot mill and continuous caster, plus the plant-wide power supply and

distribution, water treatment, lab, general layout and transport systems.

The launch ceremony of Zhanjiang BF3 plant, which was attended by CISDI and the construction company

Yancheng Steel

under planning

Baowu Group

will build its Yancheng Steel plant by the sea shore in China’s Jiangsu

Province. As the master planner, CISDI is designing a green, smart, innovative

and cost-effective ‘Factory of the Future’.

An artist’s view of Yancheng Steel, which is being planned by CISDI

Jiujiang Steel

stockyard modernised

Jiujiang

Steel’s stockyard was modernised, without any production interruption, last

April. Operating under the Jiangxi Fangda Steel Group, the stockyard features

CISDI’s eco-friendly, intelligent stockyard and online rebuild technology.

Jiujiang Steel’s eco-friendly stockyard, which was built by CISDI on an EPC basis

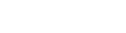

First universal

mill application

The first

application of CISDI’s universal mill development was successfully implemented

to China’s semi-continuous light rail rolling line.

CISDI created

an innovative series of universal mills, known as UMCDs, in specifications

ranging from 450mm to 1,000mm. The proprietary products have been welcomed by

China’s steel producers, who previously had to rely on imports.

A model of CISDI’s universal mill

Section 2: CISDI - Going global

CISDI launched

its UK-based overseas business operation centre last year. The company now has

a total of eight overseas offices, with the registration of CISDI Vietnam and

CISDI Malaysia.

The

subsidiaries have played a major role in strengthening communications with

clients and partners on the ground, thanks in great part to their understanding

of the local culture.

Its overseas

bases give CISDI better global resource allocation and help it compete for

overseas projects.

In 2019,

stronger relationships were forged between CISDI and steel giants

ArcelorMittal, TATA Steel and GFG.

CISDI will be

carrying out ArcelorMittal’s blast furnace rebuild in Ukraine, TATA Steel

Kalinganagar’s blast furnace supply, Isdemir and Erdemir’s blast furnace

refractory supply in Turkey, CSP’s new hot stove 4 in Brazil and LPS’s PCI

feasibility study and basic engineering.

CISDI’s

management and operations team provided operations management services for

Indonesia’s Gunung Steel Plant. The services will cover production, finance,

sales and procurement. This was a new business model for CISDI.

CISDI and its

parent company MCC made their mark at the METEC 2019 exhibition in Germany,

showcasing their unique total solutions, full-process core technology and

equipment, and intelligent and green manufacturing expertise to attendees.

ASSB’s

3.5-million-tonne plant was awarded China’s Lu Ban prize for achievements in

overseas construction. CISDI was the master designer and core equipment package

supplier for the steelworks, which is on the Belt and Road Initiative route.

Mega blast

furnace for ArcelorMittal

ArcelorMittal

entrusted the building of the blast furnace at its Ukraine plant to CISDI, on a

package supply mode.

The

5,000-cubic-metre-level blast furnace is CISDI’s second reference of its kind

for an overseas plant.

CISDI is now supplying the equipment for TATA Steel’s Kalinganagar blast furnace, which will have the same volume.

The 5,000m3-level blast furnace under construction at TATA Steel’s Kalinganagar Plant

Successful

supplies to TATA Steel’s UK plant

CISDI core equipment went operational at TATA Steel’s UK plant. The finishing mill’s scale breaker and FM’s reaction block at drive side were the customer’s most important upgrades in 2019. The customer was impressed with CISDI’s supplies and services.

The FMSB being hot-tested for the hot rolling line at TATA Steel’s UK plant

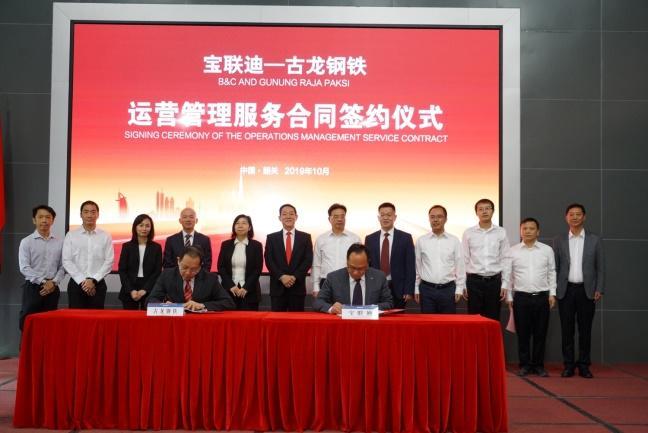

Ops management

for Gunung Steel

CISDI and

Shaogang set up B&C International Operations Management Co. to provide

tailor-made, big-data-based services for Gunung Steel’s operations management.

This ops management service mode is a breakthrough and will meet the client’s ‘hotel-style’ management requirements. It will boost Gunung Steel’s fund efficiencies, profiting and core competitiveness.

B&C and Gunung Steel‘s representatives sign the OM services contract in Shaoguan City in the Guangdong Province