Top award for CISDI’s standout project at NISCO - total factor digital production and operations and intelligent manufacturing achieved

Date:2024/9/29 Source: CISDI

A spectrum of CISDI core technologies won accolades at the prestigious China Metallurgical Science and Technology Appraisals for 2024.

A grand first prize was awarded to CISDI core tech and innovations which created total factor digital production and operations and intelligent manufacturing at Nanjing Iron and Steel United Co.

Two further projects were granted second prize and CISDI also received two awards for third place.

The Appraisals were co-launched by the China Iron & Steel Association and the Chinese Society for Metals in the country’s drive to advance steel sector tech and innovations. They are recognised as the highest standard for the sector in China.

✧ Total factor digital production and operations and intelligent manufacturing expertise

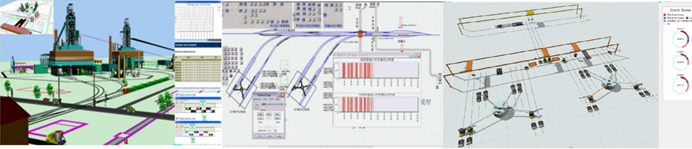

To solve NISCO’s issues of data availability, data control and decision-making during its digital transformation, CISDI delved into the steel plant’s production, operations and supply chain procedures and improved production flows by applying the following advanced tech and methods:

Smart forecasting models for hot metal’s silicon and phosphorus contents and its output and special conditions for blast furnace operation have enabled the efficient access of multiple heterogeneous data and achieved data’s real-time transmission, its fast computing and modelling analysis.

Throughout the upstream ironmaking procedures, all scenarios are smartly-sensed and cluster-controlled in an integrated way.

The Jiangsu Province steel complex now has a digital twin-based production system operating throughout - from the unloading of raw materials at the wharf to the finished product - and productivity has shown a marked increase.

The integrated control centre at NISCO, built by CISDI

✧ Critical tech of intensified down-coiler for hot-rolled strip

Inadequate, unstable and defective coilings are the challenges faced in the conventional down-coiling and low-temperature coiling of a high-strength thick and wide strip.

At NISCO, CISDI proposed an evaluation methodology and system for regulating coil’s shape quality and critical coiling parameter setup.

After in-depth research of key process data from the coiler’s drive system and the coiling shaft’s torsional vibration mapping model and control, the team developed IPR-based intensified hot strip down-coiling tech and equipment which achieves a high standard of stability and coil quality.

This state-of-the-art coiling tech has been converted into Chinese-made and controlled equipment for producing X100 and higher grade pipeline steel coils. The tech has also been applied at Pangang Xichang and Xinyu Steel’s hot strip rolling lines, resulting in tangible economic and social benefits for both plants.

The hot strip down-coiler

✧ Digital, smart ironmaking-steelmaking interface for achieving extreme energy efficiency

By forming a dynamic assessment and simulation optimisation model at a multi-flow-coupled ironmaking-steelmaking interface, combining it with an expert rules, data and mechanism model, CISDI has built a digital, smart control and optimising model which gives a full display of energy efficiency at the interface.

It calculates and plans the main orientations for enhancing energy efficiency, while generating a host of interfacial tech and models for achieving extreme energy efficiency. These results set a sector example for the collaborative use of technological process and digital, smart tech.

This transformative tech can radically change conventional production organisation methods at the ironmaking and steelmaking interface and provides the sector with the tools to maximise its energy efficiency.

It was first launched at Baosteel Zhanjiang in 2019 and increased the interfacial torpedo ladle car’s turnover rate to over 4.3, higher than POSCO’s TPC at 4.0 in South Korea. It also reduced hot metal’s temperature drop by at least 98.5 deg.C.

Successive applications at Shandong Yongfeng Steel, Jiangsu Yonggang and Liaoning Bayuquan also achieved remarkable interfacial results in lower temperature drop, reduced operational costs, higher energy efficiency and enhanced productivity.

A screenshot shows energy efficiency results at an ironmaking-steelmaking interface

✧ Super corrosion-resistant ZnAlMg plating tech

CISDI-ZnAlMg 3.0 features advanced and extremely reliable alloy plating tech and equipment.

It improves product resistance to corrosion from chloride ion and alkali, extends product service life by 5 to 15 times and reduces carbon dioxide emissions by 80 per cent throughout the product life cycle.

Hallmark features:

• Gas or longitudinal flux electromagnetic heating at the line’s process section accelerates strip’s cleaning and heating

• Patented segmented coolers at the line’s post-plating section stabilise high-quality production

• Process, equipment and production control levels rank as best of their kind in China

• The 6Al3Mg-plated coil outperforms the sector in grade C5 salt spray testing results.

The ZnAlMg plating line

✧ Mill main drive high-performance digital AC-AC frequency conversion and speed regulation tech

CISDI’s patented AC-AC frequency conversion and speed regulation solutions encompass digital tech, operation systems and critical equipment.

They meet the exacting requirements of a heavy-duty mill’s main drive speed regulation system and increase reliability, dynamism, steady-state accuracy and adaptability.

Multiple breakthroughs have been made in the development of a high-performance real-time control platform, excitation synchronous motor’s vector control, non-circulation reversing control and intermittent current compensation.

The initial application of a fully Chinese-developed hot rolling main drive was achieved at Gangchen Stainless Steel in China’s Sichuan Province. Outstanding systemic performances and dynamic responses have been achieved.

The AC-AC frequency conversion and speed regulation solutions